| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Sanhui

Model Number : TZM

Certification : ISO9001

Place of Origin : China

MOQ : 10 Kilograms

Price : Negotiable

Payment Terms : T/T

Supply Ability : 5000 Kilograms per month

Delivery Time : 20 days after order

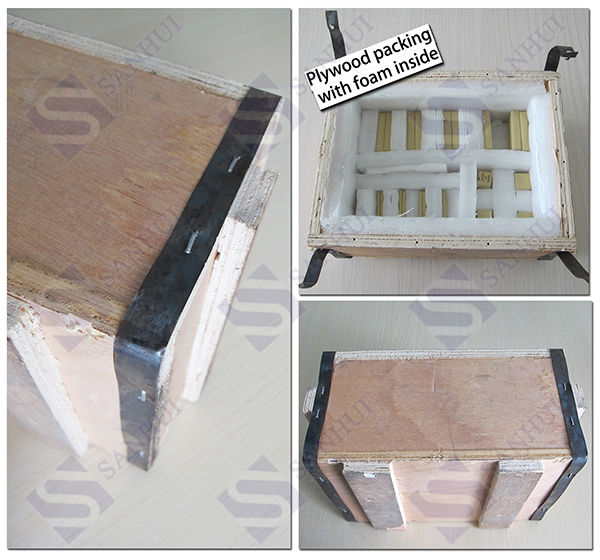

Packaging Details : Standard export plywood cases or according to customized packaging

Surface : Ground and clean

Dimension : Customized

Purity : Mo >99.95%

Density : 10.2g/cm3

Name : TZM Molybdenum bar

Application : Vacuum Furnace Molybdenum parts

Introduction of TZM alloy

TZM rod is a superalloy prepared by adding elements such as Ti, Zr and C into molybdenum matrix. It has good high-temperature properties, mechanical properties and other good characteristics, including high melting point, high strength, high elastic modulus, low coefficient of linear expansion, low vapor pressure, good electric and thermal conductivity, strong corrosion resistance and good high-temperature mechanical properties, so TZM has been widely used in many fields.

1. Purity>=99.95%

2. Density:>10.22g/cm3

3. Dimension:(dia1-110)*L<=2000(mm)

4. Ground and clean

5. Molybdenum bar pass :ISO9001:2008

6. Standard: ASTM B387

7. Material: Mo >99.95%

8. Application of TZM:

Because of its good high temperature performance, TZM is widely used in various high temperature fields. TZM is commonly used in the manufacture of electric vacuum devices and electric light source parts, and is suitable for the preparation of ion implantation parts.As a high-temperature heating element and high-temperature structural part, it is often used as the electrode of glass and refractory fiber industry. It works in 1300 ℃ glass melt, it has good performance and long service life.

9. Detail Specification of TZM Molybdenum alloy bar:

TZM Molybdenum alloy bar is manufactured as random length pieces or cut to customers' desired lengths in diameters ranging from 0.080 inches to 6.00 inches. Below are most of the standard sizes. If you do not see the size of molybdenum rod that you require, please feel free to contact us.

| Diameter | Length | Diameter Tolerance | Length Tolerance |

|---|---|---|---|

| 0.08" ~ 0.40" | <315" | ±0.005" | +0.08", -0 |

| 0.40" ~ 0.80" | <118" | ±0.010" | +0.08", -0 |

| 0.80" ~ 4.00" | <78" | ±0.015" | +0.08", -0 |

| >4.00" | <40" | ±0.025" | +0.08", -0 |

Physical performance comparison between TZM alloy and Pure Molybdenum

| Material | Density (g/cm3) | Melting Point(℃) | boiling point(℃) |

| TZM (Ti0.5/Zr0.1) | 10.22 | 2617 | 4612 |

| Mo | 10.29 | 2610 | 5560 |

| Mechanical property (TZM) | Elongation(%) | Elastic modulus(GPa) | Yield Strength (Mpa) | Tensile Strength(Mpa) | Fracture toughness(MP·m1/2) |

| Value | <20 | 320 | 560~1150 | 685 | 5.8~29.6 |

11. Guarantee purity of TZM molybdenum alloy bar

Are you looking for truly excellent quality TZM molybdenum alloy bar? Then you need us. We produce our TZM molybdenum alloy bar ourselves – from the metal powder right through to the finished product. As our input material, we use only the purest molybdenum. This ensures that you benefit from a very high level of material purity.

|

|

TiZrMo Molybdenum Alloy TZM Bar 10.22 G/Cm3 Density For Heating Furnace Images |